You are probably familiar with cotton and wool cloth, but have you ever heard of woven glass cloth? It is a unique sort of material composed of glass fibers. It makes this fabric one of the exclusive and is required for numerous purposes in several industries. We will delve into the countless advantages woven glass cloth offers, where it finds application across a range of industries and some quick trivia on how this textile marvel is created as well its origin story.

Woven glass cloth is extremely durable, which is one of the key reasons why it has so many advantages. In spite of it being composed by Glass Filaments and because the way how these filaments are woven, makes this material a strong fabric that is very resistant on most cases. This is a key strength for environments in which things can get bumped (easier than touched) or knocked about–factories and construction, to name two. Durable materials are key to operating safely and effectively in these conditions.

One excellent thing about woven glass cloth is effective in heat and fire resistance. One salient feature of glass is that it can withstand substantial heat without melting or burning. Woven glass cloth is nonconductive which makes it ideal for insulators, protective clothing and in saturated applications where heat resistance matters most. Thus, it is a potential candidate for many industries suffering the trouble concerned with high temperatures.

Woven glass cloth finds a number of applications across different industry verticals. In the construction industry, anhydrite is often added to strengthen concrete. This is important for both the safety and stability of buildings and other structures, as well-made ones can endure more wear before needing repairs or replacement.

Glass reinforced plastics have been used for thousands of years. Tools for Cutting Glass and Understanding the Uses of InsulationMaterialsIn truth, glass fibers have been spun out to make insulation materials used as efficient, thermal insulators since not only present day humans but also greatlyantediluvian Egyptians and Greeks went about their daily business. They already knew the advantages of glass! Yet, it wasn't until the 20th century that woven glass cloth began being used in a lot of different industries.

A third method is known as twill weave. This weave takes the fibers and weaves them 90 degrees to each other creating a bias cut which makes for an extremely strong, yet flexible textile. Twill weave is frequently used where the fabric must fold or bend, for example in clothing and upholstery. The weave can also be used across a broader field of applications because many materials need to have some flexibility and/or stretch.

Multi-layered composites also include woven glass cloth. A composite is a material made of at least two different types substances that when combined, give the overall material properties different than those found in its component parts. Above is the resultant fiber/epoxy composite, often using woven glass cloth as a reinforcing material.

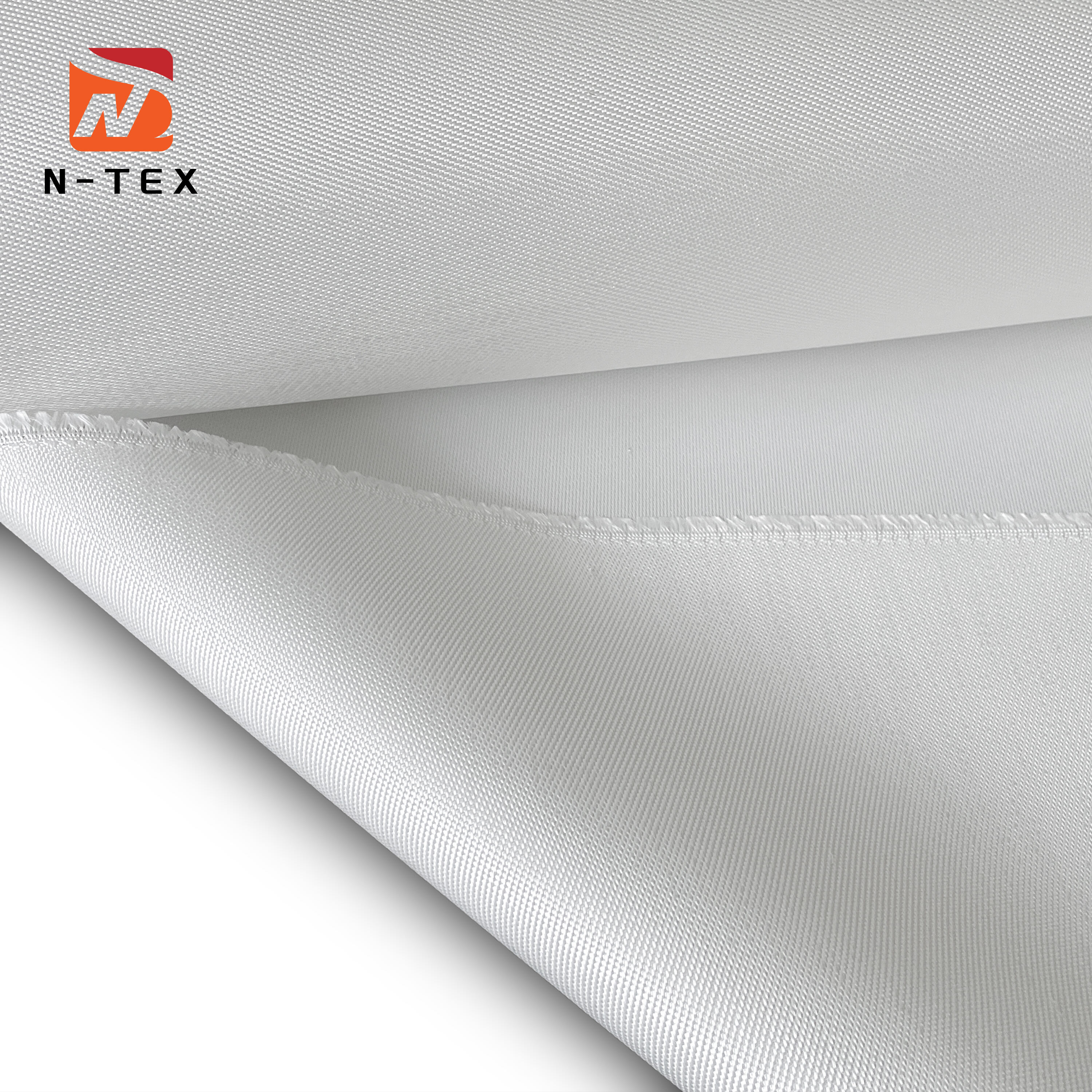

We are very strict about the quality of our woven glass cloth as we believe that our products are the soul and heart of every company. Before we ship, each item is inspected for the highest quality. We also test the thickness, gram weight and the color of the product to avoid any after-sales problems.

Our company manufactures mainly silica mats and super mats. To satisfy the demands of our customers we are able to customize our products by using different colors and coatings. We also provide woven glass cloth. We also have various sizes of fire-blankets which can be used for high-temperature operations as well as fire safety and other fields.

Each of our woven glass cloth is installed with a security inventory system, in the event that a customer requires it, they need us to ship it at the first time. The annual volume of our products could reach 5 million meters, the delivery time of ordinary products is generally about 10-15 days. Our delivery rate is rapid, and for more than 3000 customers across the world, and exports to over 20 countries around the world.

Nanjing Xinwei High Temperature Material Co Ltd is a reputable producer of high-silica fabrics covers a space of the size of 20 000 square meters There are woven glass cloth in the factory Our production capacity can reach the 200 000 meter mark per month and our inventory is adequate to ensure that the first shipment is delivered We also have customers from all over the world and we are willing to provide top quality service to every customer