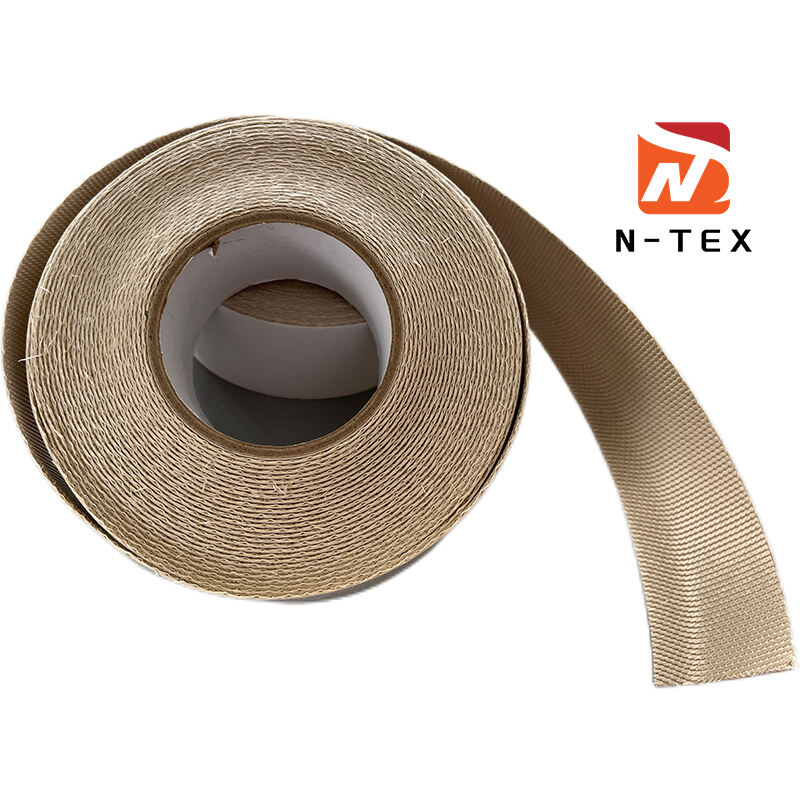

The material itself if pretty special — silicone coated fiberglass. Sounds fancy, right? This second layer is what makes them silicone injected. A process that makes the materials so strong and also offers ant two resist facility. The shockwave is capable of taking on harsh elements like wind, rain salty sea air and snow. The problem for such and other similar, just want to produce havoc in some of the Custom ROMs but as any official stock can be charged more than a working customized. Red loctite is necessarily hard and will hold the piston in good as new even if it gets hot enough to glow red. This is exactly why Fiber Glass Products of NEW-TEX makes so much sense, it can be used in many applications outside of just adhesive uses where this roving style material does a great job at preventing heat degradation without breaking down itself.

Silicone coated fiberglass has the advantage of being easily hand-cut and molded. Hence it is scalable to quite a bit. You can also use it just to cover macaron equipment and act as a barrier, or even on top of your dishes instead of an oven insert. It is also useful for protecting electronic devices, as it prevents them from becoming too hot and shutting down. Silicone coated fiberglass, by NEW-TEX is essentially a flexible and versatile composite utilized in many industries.

Helped by the silicone insulation poured this fiberglass wire also insulates against intense heat. The pads can handle 500°F without melting or catching fire. The high temperature resistance is what makes good silicone accessory heat feature for grill mats and baking sheets which are exposed to much higher temperatures when you cook with them. Furthermore, NT Mat with fiber is frequently employed in construction uses where high average temperatures are required to maintain the strength and steadiness of building materials; such as insulation boards that must deliver riotous action while also delivering energy efficiency.

Note that silicone coated fiberglass is essential for safety reasons. It is the stuff they make special clothes and gear out of for firefighters because it can take a good bit of fire. This is a useful feature especially when they are surrounded by fire in dangerous emergency situations. Some examples from the firefighters that use this fire-resistant material are Silicone Coated Fiberglass. It literally can be observed in curtains, carpets and also on the walls or roofs of buildings. This means that more jobs are not cut and spread across the states.

Silicon coated fiberglass is also good because of their non-stick surface. So it is simple to clean and we all know there are going to be times you have got this cup!! Similar to how chefs use silicone coated shade for their pans and trays in a kitchen. These liners are also dry and so there is less food stick to them when you finally cook in it: making clean up after its use easier, faster. Similarly, Fiber Glass Products from NEW-TEX can be employed in factories and industrial workplace to apprehend the dust or debris. This measure will aid in creating a clean and safe workspace for all those who are associated.

The products we sell are kept in a secure inventory, so that we can ship the product to the customer whenever they require it. Our annual production of products may exceed Silicone coated fiberglass. Delivery times for normal products can be between 10 and 15 days.

Our company makes primarily super mats and silica fabric. Our products can be customized to meet the needs of the customer. different colors and coatings, to meet the requirements of the customer, and also provide good service. We also have different sizes of fire-blankets which can be used for high-temperature operations as well as Silicone coated fiberglass and other fields.

Our company is very rigorous on the quality control of our products because we always hold that the quality of products is the foundation of a company. Before we ship, each product is examined for the highest quality. We also check the thickness, weight in grams and the color of the product to avoid any Silicone coated fiberglass problems.

Nanjing Xinwei High Temperature Material Co Ltd is a reputable producer of high-silica material covers an area of 20000 sq meters The factory is equipped with four lines of production The factory can produce a capacity of 200 000 metres a month and an inventory sufficient to ensure the first delivery We have clients from around the world and are Silicone coated fiberglass to delivering the best standard of service