The fibreglass fabric used in fabrication is woven from extremely fine strands of glass fibers. Picture it as if small threads are being twisted and crisscrossed to make a sturdy cloth; this is what fibreglass matting does! So that means it is little a strong but also tough and tough stuff. The strength is one of the major advantages that you can get when using fibreglass matting. It is highly pressurize and resistive; thus it does not break. This can be really important for stuff that is supposed to be strong, like boats which go on the water or cars which travel quickly.

One other thing about fibreglass matting is that it truly lightweight. Which makes this portable and fully capable to play with in various projects. It may be soon light but it's incredibly strong! Fibreglass matting is resistant to weather, chemicals and fire. It will not be easily destroyed by rain, snow or the heat. This is why fibreglass matting makes a superb material for reinforcing an assortment of objects.

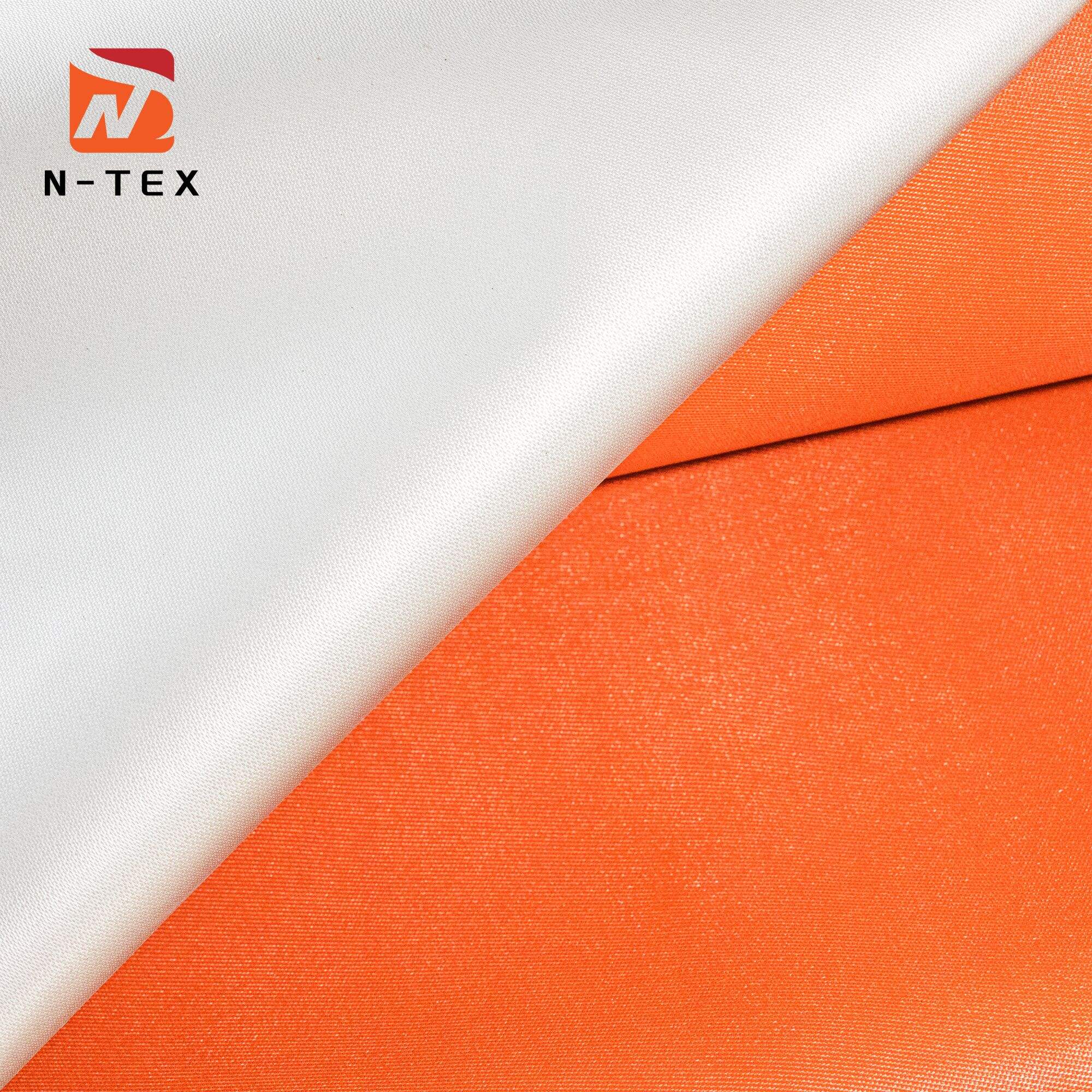

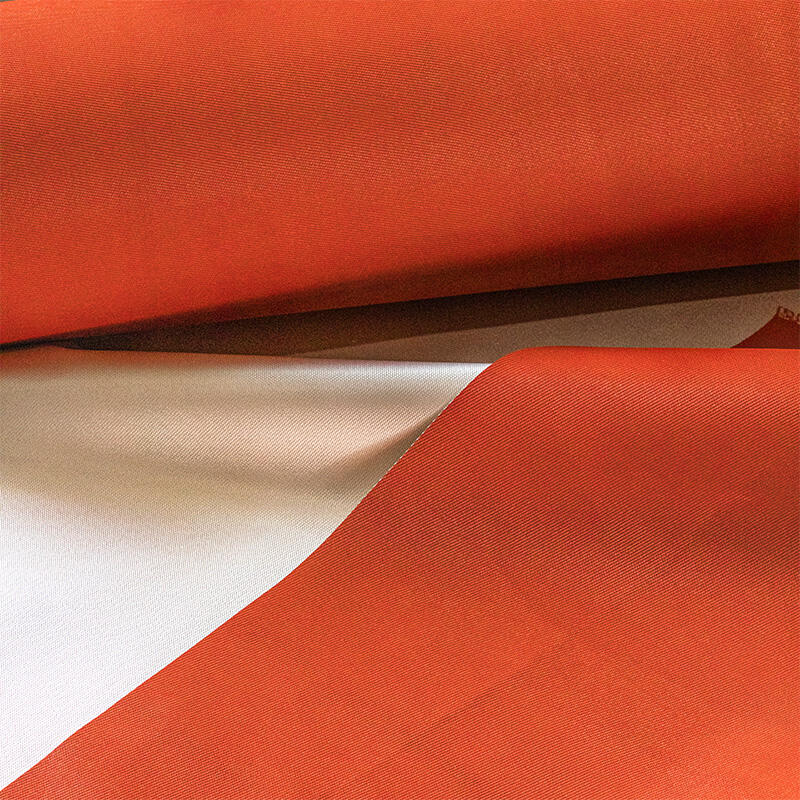

It is worth pointing out that fibreglass matting has several weaves which are more suited to certain types of work. As an example, a plain weave is one where the very fibers are woven over and under each other. It makes a smooth working surface. Still, it might not be as dense as other weaves. In other hand, twill weave has a unique diagonal pattern that makes it one of the strongest and most durable. However, this kind of weave may be slightly trickier to work with.

Fibreglass matting is a popular choice to reinforce your structure as it vastly improves the strength and life span of that area. The process involves placing the matting directly down over an object to be enhanced. It is followed by a stick referred to as resin or epoxy. This hardens the material, allowing it to form a strong layer that can withstand stress and pressure.

The fibers can be used in a variety of places such as boat hulls, car bodies and even houses. The same structures strengthened and extended in life by simply incorporating fibreglass matting. So, if a building has fibreglass matting in its structure then the same can defend it against foul weather and diversified complex problems for years together.

Skilled workers use special techniques to make fibreglass matting as strong as possible. These workers are experts in how to weave many different ways and forms together with each other which releases a material that is extremely effective. For instance, they could integrate various kinds of weaves to develop a more resistant weave object.

Fibreglass Matting can be used in many forms as it is an incredibly versatile material. An example is in pipes and tanks that contain chemicals; a carbon fibre coating here helps reinforce them, making sure they remain secure. It can also be used for buildings in areas that are most affected by an earthquake or strong gusts of wind. So, for those of you who live in areas where these types of natural disasters can occur the use fibreglass matting may make your dwelling a touch safer.

woven fibreglass matting company is primarily producing super mats and silica fabrics. To meet the requirements of our clients we are able to customize our products using different colors and coatings. We also offer a first-class service. We also have various sizes of fire-blankets that could be used in high-temperature applications in fire safety, as well as other areas.

Nanjing Xinwei High Temperature Material Co Ltd Professionally produced high-silica fabric that covers a total area of 20000 sq meters There are four production lines in the factory The capacity of our production can exceed the 200 000 meter mark per month and our inventory is woven fibreglass matting to ensure that the first shipment is delivered We have customers from all over the globe and are committed to providing the highest quality of service

Our inventory is kept in a safe woven fibreglass matting so that we are able to deliver the product to the customer as soon as they need it. The annual volume of our products could reach 5 million meters. The delivery time of ordinary products is generally about 10-15 days, the delivery speed is fast, for more than 3000 customers across the globe, we export to more than 20 countries in the world.

Our company is very strict in the quality control of its products, as we are convinced that quality of the product is the foundation of any company. Every item we send is tested for high-quality, and we have a woven fibreglass matting eye on the thickness and gram weight of each product. We also check the product with color difference to avoid after-sales problems.