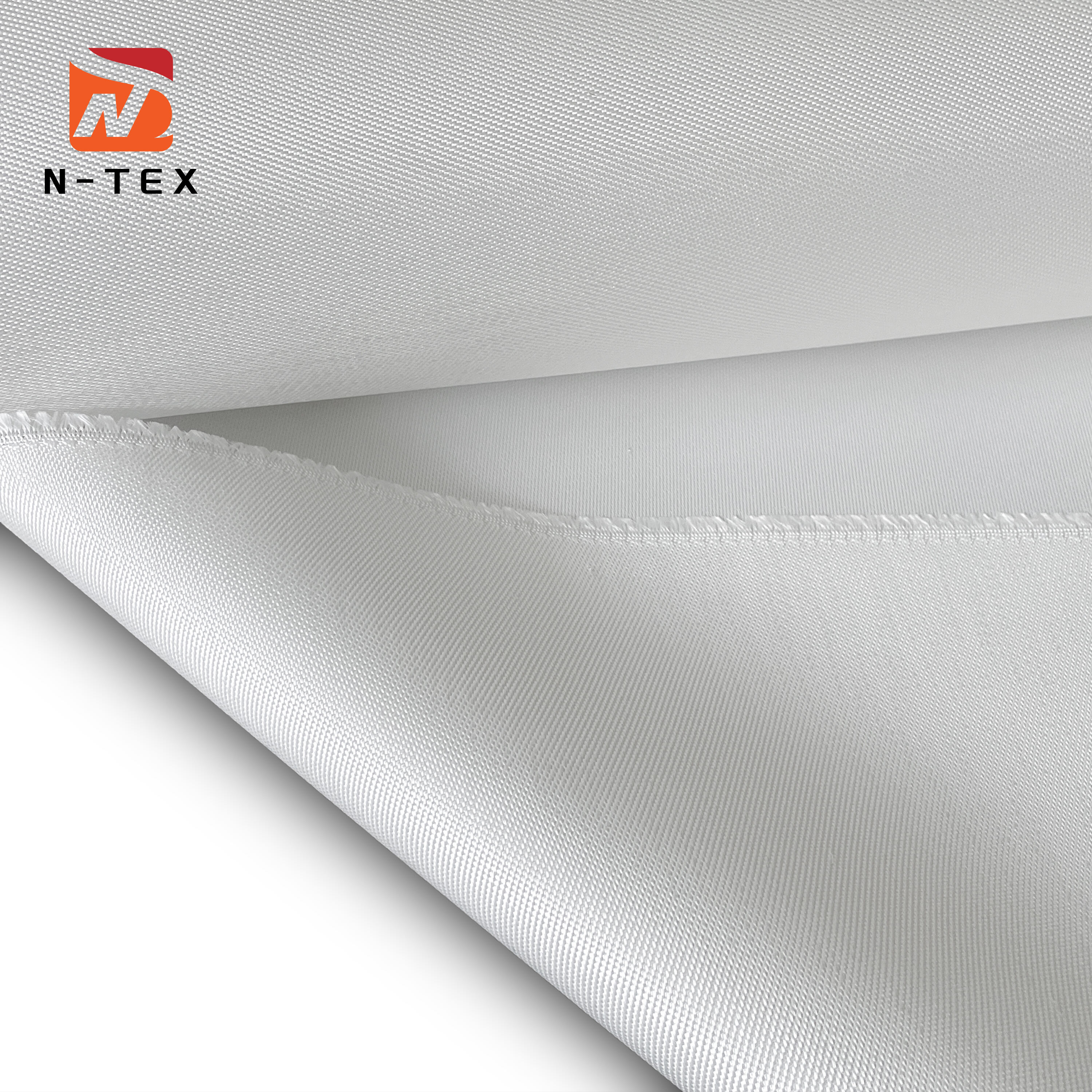

Do you know about glass microfiber? Fiber-optic cables are a unique material crafted from bundles of small glass filaments. These strands are on a tiny scale that you cannot perceive them along with your eyes, but they're very much crucial in plenty of different goods. While these fibers are extremely thin, glass microfiber is incredibly sturdy and durable. As many know, glass is already a strong material and when it gets converted into these tiny fibers they become even stronger. These little fibers are spun and woven into a fabric that can withstand quite the beating. This means it can go a long time without breaking or deteriorating.

Glass microfiber has a lot of positives for various products. Delivery packages has many perks and one of the best things about it is its extraordinary strength. It is also used in many different types and varieties of jobs because the glass microfiber can withstand a lot more pressure than other materials are able tohandle. As an example, it can be used in applications that are either high load or operate at extreme conditions due to its strength. And the best part about glass microfiber is that it's incredibly lightweight. These include glass microfiber which is powerful yet much quitter than many substances This is particularly crucial in places like airplanes since every bit of weight counts. It can change the way in which an airplane flies if it is too heavy. Thus, lightweight materials such as the glass microfiber enables a better and efficient performance of aeroplane flying.

There are several other materials glass microfiber can be combined with, each one enhancing its standard abilities even further. For instance, adding glass microfiber to plastics makes them stronger while increasing their resistance to heat without melting or warping. It can also be added into concrete to give it more tensile strength which means less cracking over time. This is an important condition for long-lived buildings and roads. Glass microfiber can even be used in paint to prevent chipping and peeling, making surfaces look good for longer. In all these industries and others, the use of glass microfiber allows other materials to do a better job for longer periods of time.

Glass microfiber is well-known in many industries because of its wide-range utilizations. It is commonly used in the airplane industry to help make parts for planes and spacecrafts that are lightweight yet strong. This, of course, helps keep airplanes aloft while retaining the ability to carry heavy weights. And in the automotive field, you will also find this kind of technique for manufacturing high temperature and pressure demanding parts–one where such properties are especially geared to cars/trucks which revolve at a very fast rate. Glass microfiber is used in the building industry, by adding it to concrete and other materials this will increase their only strength. This means that buildings, bridges and other structures could last longer or deal with extreme weather.

Glass micro fiber is a recently recognized material which has revolutionized a few businesses. All these characteristics of the material have encouraged many people to love this fabric for a vast number of applications as it is so strong, cannot let liquid or light heavy particles pass through & can make utilization an alternative way. Due to the annual increase in size and development of technology, glass microfiber should be applied also undreamed hour --- after all this way as well would expect so. That means that it will be a much more vital material in the future, as countless products and sectors can benefit from its properties.

Nanjing Xinwei High Temperature Material Co Ltd is a well-known producer of high glass microfiber covering an area of around 20 000 square metres There four production lines within the factory The capacity of our production can exceed the 200 000 meter mark per month and our inventory is adequate to ensure that the first shipment is delivered We have customers across the globe and are determined to provide the best quality service

Our company manufactures mainly super mats and glass microfiber. To meet the requirements of our clients we are able to design products by using different coatings and colors. We also provide first-class service. We also offer different sizes of fire-blankets which can be used in high-temperature applications or fire safety as well as other fields.

Our company is very strict in the control of quality of our products because we always glass microfiber that the quality of products is the heart of a company. Before we ship, every item is inspected for high-quality. We also evaluate the thickness, gram weight as well as the color of product to avoid any after-sales issues.

Each product we sell is glass microfiber inventory that is set up, in the event that a customer requires it, we can ship the first time. The annual volume of our products could reach 5 million meters. The standard delivery time is generally about 10-15 days. Our delivery speed is quick, for over 3000 customers around the globe, we export to over 20 countries around the world.