Before you even think about starting, acquire all correct tools. This is really crucial for your protection. In order to avoid injury you will need gloves (to protect your hands), safety goggles or other device(s) for protecting eyes, a mask that covers the nose and mouth while cutting cloth, as well as material shears. Wearing PPE is absolutely essential, as fiberglass can be an irritant to your body including skin and lungs if you make contact with it.

For example, if the wall has a hole in it then look for that area to clean up really good. Again, check for any loose or rusty components that will need to be taken off. Get down under the car, clean up around weld area and use resin to put a cloth onto surface. For this, the resin should be applied in small areas; starting near to the middle of that section and continue onto its sides. This is going to ensure an even application.

Then, lay the fiberglass cloth on top of that which will be wet out with resin and smoothed for air bubbles or wrinkles using a brush or roller. This process is especially critical because air bubbles can reduce the strength of your repair. Dry the resin After you have smoothed it out. After it dries you sand off the extra material and reapply if necessary.

Step 1: Cut Fiberglass Cloth Cutting your fiberglass cloth down to the appropriate size for your intended project. Well, you should probably use your best guesses…but let them sit for a while and then throw on some gloves (and goggles because this stuff can get pretty airborne!), wrap the cloth with it being sure to cover both ends well. Being careful is always important! Combine the resin after it dries and follows all of the instructions, then added on how you want to collect your cloth. Just pay attention to its terms and follow it properly for better working.

Now apply the resin on to where your fiberglass will be using a brush or roller. Remember that you should cover it in a thin layer and work quickly or the resin can begin to harden once again with 15 minutes. Whether you are using woven mat, or any other type of sheet, after applying the resin neatly place it on top. Repeat the step of painting a brush or roller again to get rid of any air bubbles, or wrinkles that might have popped up. This is so that it makes sure a great bond.

Then the fiberglass cloth and another coat of resin are laid on top to get full coverage. This will assist the cloth stick to the surface greater than ever. Please ensure that the resin has dried before you attempt to sand away any over flow. If you realize so adding another set of resin + hardner layer on top if necessary could do the trick.

Chopped Strand mat on the other hand is 'hairy' compared to fiberglass cloth. The result is a great solution for beefing up weaker sections of projects, or adding some additional muscle where it counts. Another thing about fiberglass cloth is that it resists water, which makes it ideal to use in a wide range of areas including boats or other outdoors applications where there will be adverse conditions. This makes so your repairs do not fail as fast.

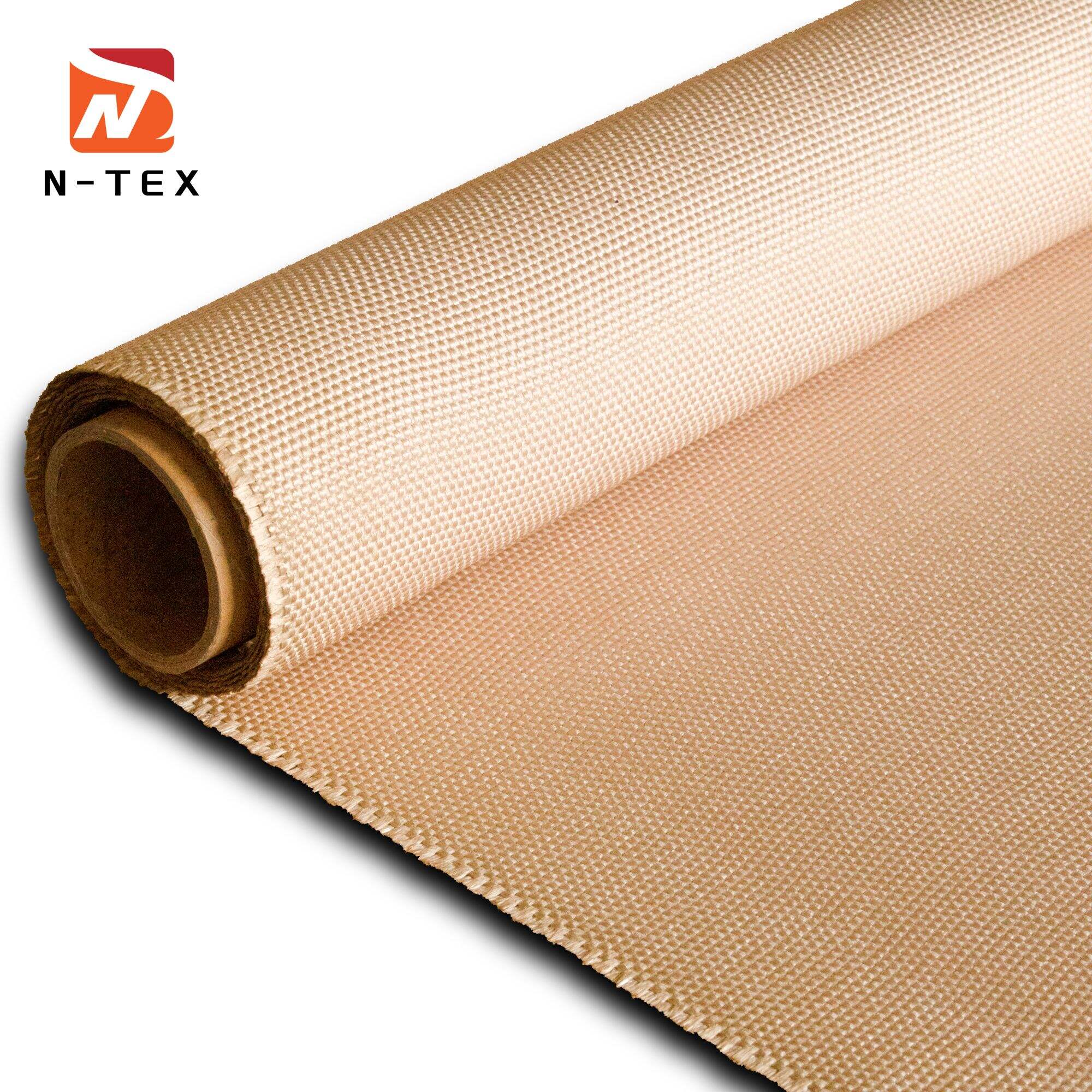

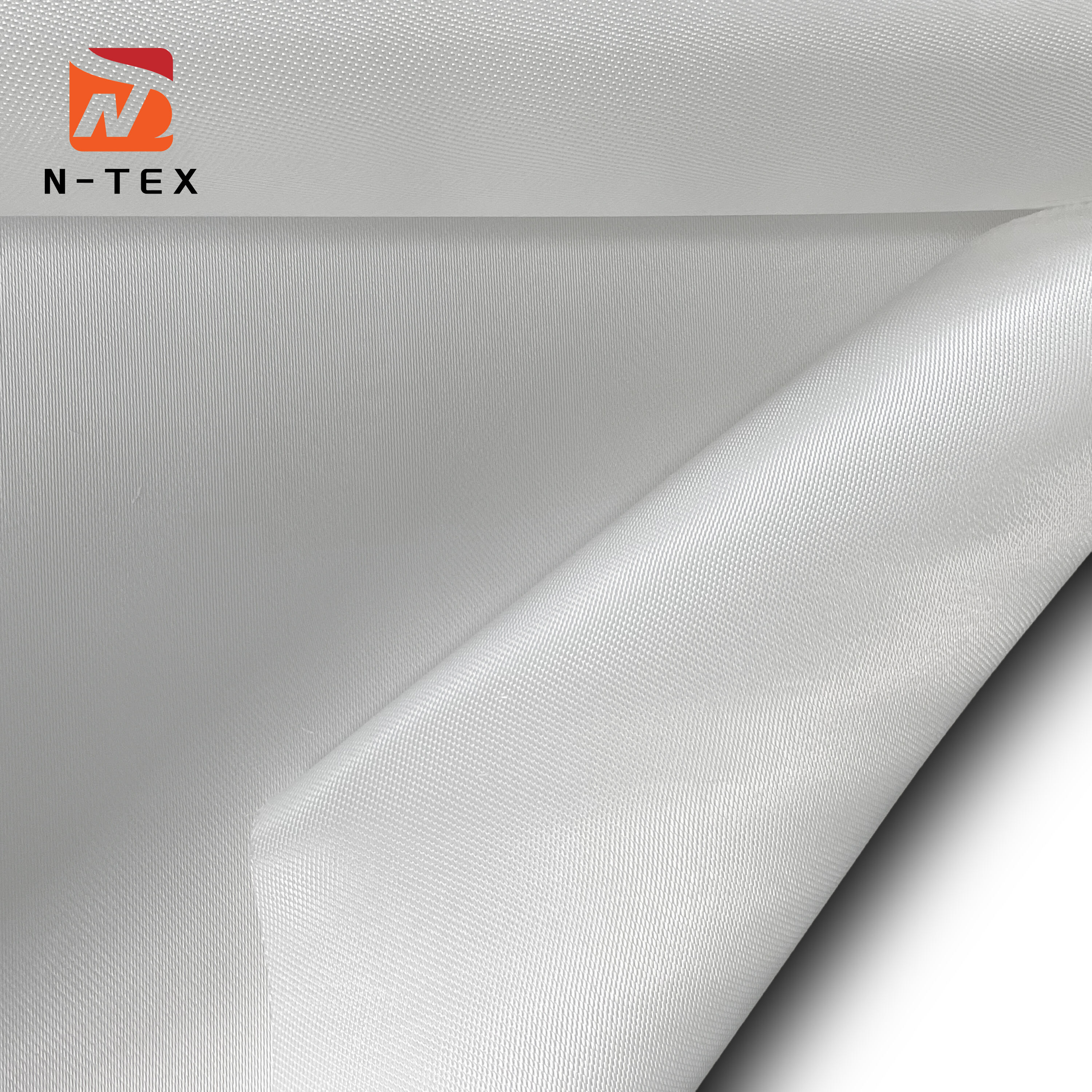

Our company makes primarily super mats and silica fabric. Our products can be customized to meet the needs of the customer. different colors and coatings, to meet the requirements of the customer, and also provide good service. We also have different sizes of fire-blankets which can be used for high-temperature operations as well as using fiberglass cloth and other fields.

Our inventory is kept in a safe using fiberglass cloth so that we are able to deliver the product to the customer as soon as they need it. The annual volume of our products could reach 5 million meters. The delivery time of ordinary products is generally about 10-15 days, the delivery speed is fast, for more than 3000 customers across the globe, we export to more than 20 countries in the world.

We are very strict about the quality of our using fiberglass cloth as we believe that our products are the soul and heart of every company. Before we ship, each item is inspected for the highest quality. We also test the thickness, gram weight and the color of the product to avoid any after-sales problems.

Nanjing Xinwei High Temperature Material Co Ltd is a reputable producer of high-silica material covers an area of 20000 sq meters The factory is equipped with four lines of production The factory can produce a capacity of 200 000 metres a month and an inventory sufficient to ensure the first delivery We have clients from around the world and are using fiberglass cloth to delivering the best standard of service