There are a great deal of various things that individuals use with fiberglass, from boats to automobiles and even aircraft! Fiberglass is that perfect material for all these stuffs because this factor provides strength as well light weight to reduce pressure on the load. But fiberglass also has a tendency to break down or stage separate. There's a solution to this and it called fiberglass welding. So, buckle up and follow this article to have a better idea of how does fiberglass welding works… because knowing is fixing!

Drawing an analogy with sewing, where we sew various parts into a whole using thread — here too instead of two spools in fabrics (synthetic threads) and special techniques promote doing this job perfectly well in fiberglass. Step 1: Cut small pieces of fiberglass cloth to glue over the area that needs fixing. Then, you want to take out a brush and start painting this resin over the cloth. This will allow the resin to set up and harden, it keeps the cloth in place while creating a very rigid area. These are what we call a patch in programming anything. Where soon we can slide on clothe and resin covering all the repair, if such a large one.

It does take some practice to get fiberglass welding right but do not worry! The more you practice, the better at it that you become! The following are some easy things you can do to expedite the process:

If the patch looks thicker than you wanted, it is because there was either too much resin or cloth with an excessive amount of resin. This can be remedied by smoothing it out with sandpaper so that is flush with the surface around it.

Either way, this will inhibit the patch from bonding to the wall if it is already falling off and that has given you inspiration for your repair project. Be sure to lightly sand the area before applying the resin so it has something to adhere to.

If the resin is not drying, or it feels tacky once dry then your workspace may be too cold and/or humid. In that case, consider relocating to a dry warmer southerly exposure and let it almost completely desiccate further on its own.

Cracking or peeling: In the event that a patch cracks and/or begins to peel, this could be indicative of either too thin applying it at stresspoints. If this were completely fixed by applying a second, or even better, third layer of cloth and resin to strengthen it.

The products we sell are kept in a safe inventory so that we can ship the product to the client whenever they fiberglass welding it. Our annual production of goods can go up to 5 million meters. The time to deliver ordinary items is typically between 10 and 15 days.

Our company is very strict in the control of quality of our products as we believe that the quality of products is the soul of any company. Before we fiberglass welding, every item is inspected for the quality. We also measure the thickness, weight in grams, and color of the product to prevent any after-sales problems.

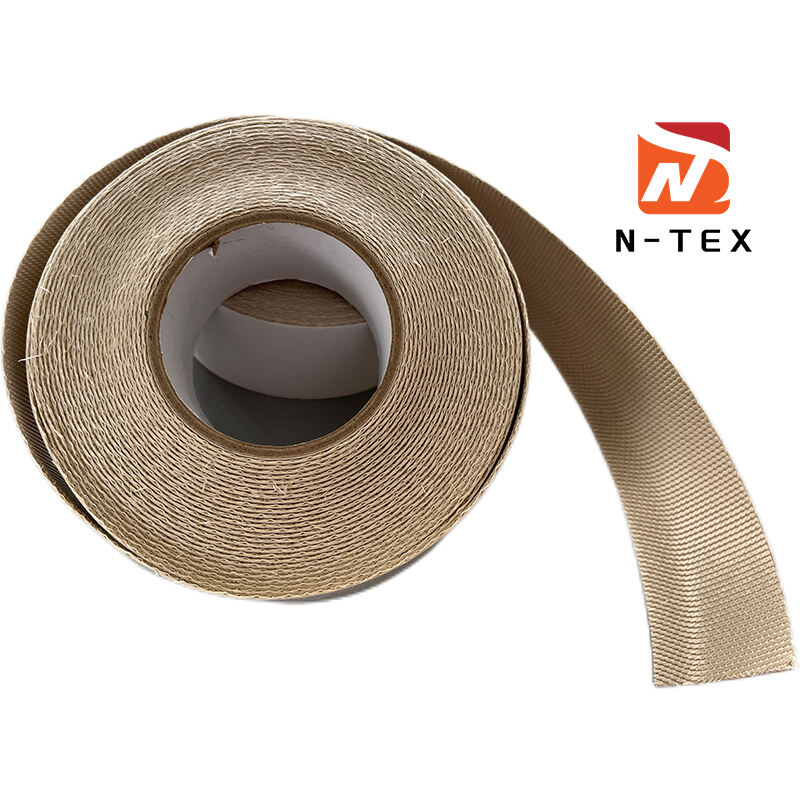

Our company makes primarily super mats and silica fabric. Our products can be customized to meet the needs of the customer. different colors and coatings, to meet the requirements of the customer, and also provide good service. We also have different sizes of fire-blankets which can be used for high-temperature operations as well as fiberglass welding and other fields.

Nanjing Xinwei High Temperature Material Co Ltd Professionally produced high-silica fabrics covers a space of fiberglass welding The factory is equipped with four production lines Our production capacity is around 200 000 meters per month and our inventory is large enough to ensure that the first shipment is delivered Additionally we have customers from all over the world and we're prepared to provide the best high-quality service to each and every client