Fiberglass mats are thin sheets woven from fine glass filaments. This type of weaving process makes the mats durable and at same time flexible, this is achieved because they can bend and stretch without breaking. Due to some of its unique properties such as resistance to weather, rust and chemical corrosion; many people use fiberglass mats in various building materials and manufacturing. Fiberglass mats can be cut into any shape or size you want, which is great. Which makes them ideal for various sorts of projects from little arts, and crafts to complete building careers.

So fiberglass mats actually have lots of good things working in their favor when it comes to your projects. One is the light weight of it, so that makes them easily portable and handle. Part of this is their incredible strength, as they can be used under high load conditions. Furthermore, Fiberglass mats are one of the easiest types to work with which is key when building or repairing anything. They are resistant to water as well as heat and chemicals, which is perfect for areas that might have all or one of these elements present. A con about the fiberglass mat is that it can be expensive and if you are doing larger projects but one of materials, then your final cost will significantly increase. It reminds you in advance so that you remember it every time when planning your work.

You will want to be sure that the scissors you plan on using are quite sharp since fiberglass mats can easily distort or get pushed out of place. Be sure to put on gloves and a dust mask so you not only protect your hands but also prevent the glass fibers from coming off of the mats there. Not only do these fibers irritate the skin, but they can also be harmful when inhaled; thus, precautions must be taken. Measure before you cut and use a ruler to mark where you want the mat to be long ensuring it is straight. From there, make a cut along that line. As I mentioned above, make sure that you follow all the safety codes provided on your fiberglass mats and take additional caution as you work with them. By taking these safety precautions the working experience is more pleasant and safe.

Boat Building- In boat building, Fiberglass mats are used extensively. This is because they are water and chemical resistant which makes them ideal for a wet surrounding. Also, given how light they are you don't have to struggle too much when it comes time for boat construction.

Automobiles: Fibre glasses mat are frequently used in car repair, specifically for the fix of auto bodies. They are durable & mouldable over areas on the car where you need repair.

Electrical Safety: Another very common application where fiberglass mats are used is in electrical insulation. The metal components are non-inflammable and heat resistant, which ensures that they do not catch fire these can be safe because of their inherent ability to resist electricity.

Roofs: Last but not least, it is normal for fiberglass mats to be used on roofs. They tend to be both very strong and light, helping support the roof without much added weight. This alone makes them an attractive choice for roofing materials.

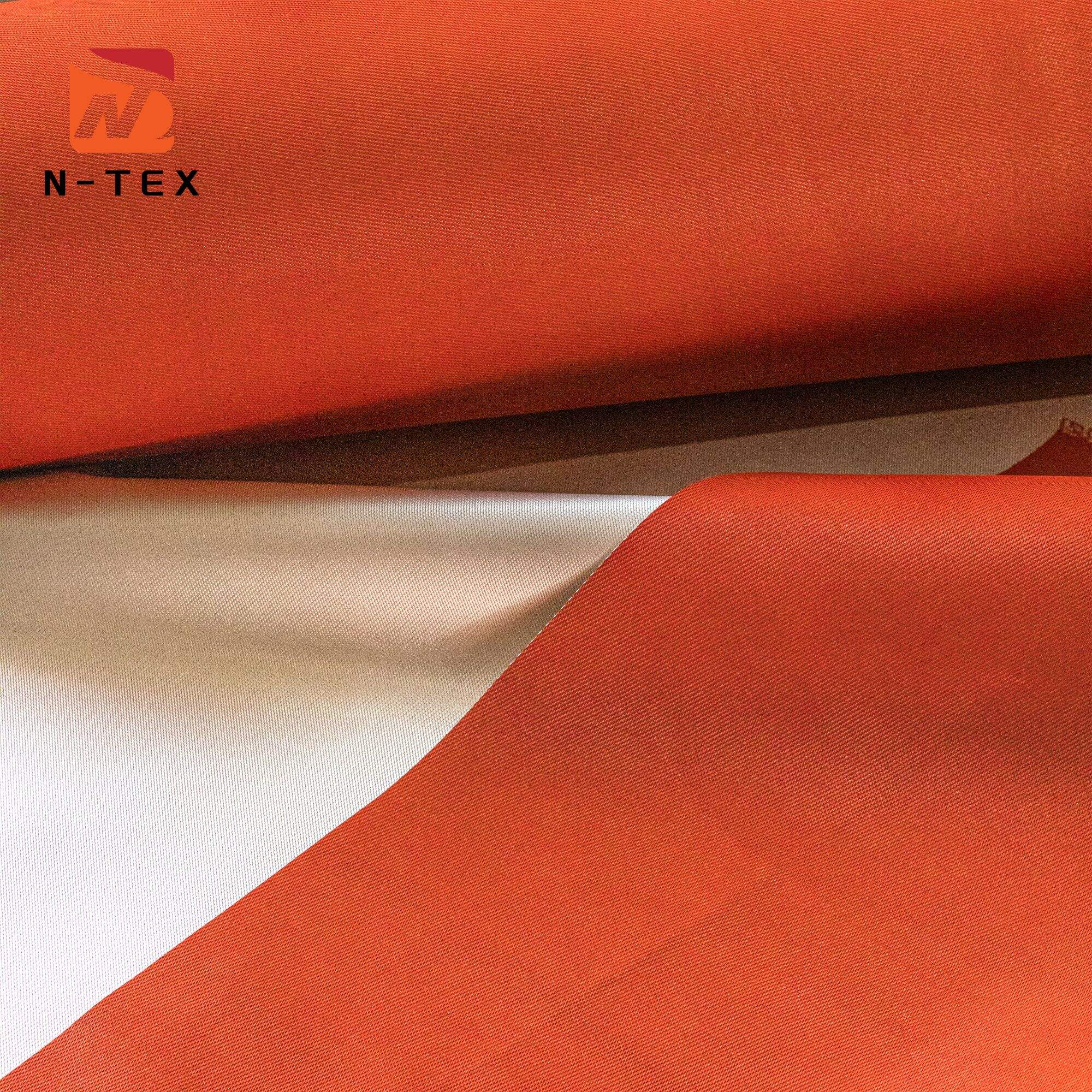

Our fiberglass mats is primarily involved in the production of super mat and silica fabric. To meet the requirements of our customers we are able to design products using different coatings and colors. We also provide excellent service. We also carry different sizes of fire-blankets that can be used for high temperature operations, fire safety, and other fields.

The products we sell are kept in a secure inventory, so that we can ship the product to the customer whenever they require it. Our annual production of products may exceed fiberglass mats. Delivery times for normal products can be between 10 and 15 days.

Our company is very strict in the control of quality of our products because we always fiberglass mats that the quality of products is the heart of a company. Before we ship, every item is inspected for high-quality. We also evaluate the thickness, gram weight as well as the color of product to avoid any after-sales issues.

Nanjing Xinwei High Temperature Material Co Ltd Professionally produced high-silica fabrics covers a space of fiberglass mats The factory is equipped with four production lines Our production capacity is around 200 000 meters per month and our inventory is large enough to ensure that the first shipment is delivered Additionally we have customers from all over the world and we're prepared to provide the best high-quality service to each and every client