Surfboards are super cool, and many people just love surfing!!! While surfing may be both a sport and just for enjoyment on the ocean playing with waves. Fiberglass ClothOne key ingredient in the creation of surfboards that you may not know about is a material called fiberglass cloth. This particular type of cloth could be considered one-of-a-kind fabric that is used to ensure surfboards are stronger and more efficient in withstanding high waves. In this article, we will visit the following topics:Why use fiberglass cloth on surfboardsHow to choose a weight of Fiberglass ClothDifferent types of Weaves and finishesHelpful tips for using FilberglassClothThe best option when it comes down making your own wooden boards.

Surfboards use the fiberglass cloth for two things: To make them strong and durable to last a long time. The fiberglass cloth that is used to produce a surfboard helps the board resist rough and tough water. It also serves as protection for the surfboard against things like water damage, scratches etc. As an illustration: If your surfboard gets caught on something hard, like rocks or wet stone The fiberglass fabric is has the potential to protect it against snapping. Apart from that, fiberglass cloth serves to make surfboards lighter. This is invaluable for surfers as a lighter board to carry and maneuver in the water, can increase your surfing pleasure substantially.

If you prefer, read our comprehensive and free fiberglass guide to help choose the perfect weight of cloth for your surfboard. The weight of the cloth, too changes how strong and flexible your surfboard will be. Thicker fiberglass cloth will add weight to the finished surfboard compared to lighter glass, making it stronger. Then you need to strike the balance between having a strong board with healthy buoyancy that is still easy enough to lug around. Surfers working on different kinds of boards, or using them in various types of waves would employ a variety fiberglass cloth weights. Talking to a professional or searching the internet for particular board weights of fiberglass cloth can be very beneficial in determining what will work best for your surfboard.

There are a variety of styles called weaves with which fiberglass cloth is made, depending on the finish. Plain weave is the simplest and most common way fabric can be woven together, creating a pattern resembling that of a checkerboard. There are also others such as twill, and satin weaves which have more complex or interesting patterns. These various designs can create differences in strength and flexibility of the board. The finish in the fiberglass cloth and its existing grip plays a vital role on how the board behaves with water. You may select the glossy finish, which is shiny and vivid or a matte one that sparkles less. The finish only affects visual and tactile; changing the way a surfboard looks or feels, but not how it rides in the water.

Practise is necessary whilst working with fibreglass cloth but it's more to do about getting that desirable end result for the surfboard and how much you enjoy when using. Step 1: Clean & Prep Surfboard Before Working With Fiberglass Cloth The presence of any dirt or bumps on the board while applying the cloth may indicate future problems. Cut the fiberglass cloth to size and shape that suits your needs for creating a surfboard. Laps the fiberglass cloth over edges of board This strengthens them and increases their longevity. After that, spread the resin evenly along with fiberglass cloth. It is crucial as equal distribution prevents the formation of air bubbles or lumps, which can impact the surfboard.

Fiberglass fabric has been the best in making surfboards for years. It's so popular because of how strong it is, the fact that it lasts more or less forever and crucially — the stuffs light as a feather…meaning lighter boards to surf on. Fiberglass Cloth is also easy to work with and it can be formed into any design surfboard you desire. Fiberglass cloths have different weights and styles, but also may be woven differently with varying bound fiber sizes -- all of which will directly affect the outcome when making fiberglass composites for surfboards. Thanks to fiberglass cloth, surfboards can be strong enough to endure the rigours of this gnarly sport yet so light that those awesome waves are much easier to catch at!

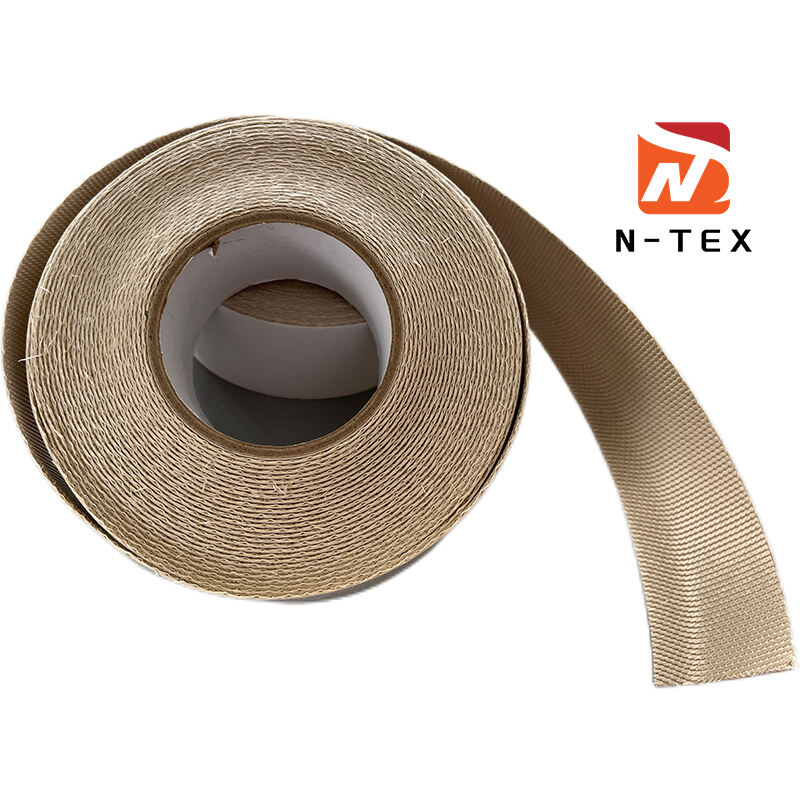

Nanjing Xinwei High Temperature Material Co Ltd Professionally produced high-silica fabric that covers a total area of 20000 sq meters There are four production lines in the factory The capacity of our production can exceed the 200 000 meter mark per month and our inventory is fiberglass cloth for surfboards to ensure that the first shipment is delivered We have customers from all over the globe and are committed to providing the highest quality of service

Our company mostly produces fiberglass cloth for surfboards and silica fabric. To meet the requirements of our clients we are able to design products using a variety of colors and coatings. We also provide top-quality service. We also can make various dimensions of fire blankets, which can be utilized for various fire safety applications and high temperature applications.

Our company is very strict in the control of quality of our products because we always fiberglass cloth for surfboards that the quality of products is the heart of a company. Before we ship, every item is inspected for high-quality. We also evaluate the thickness, gram weight as well as the color of product to avoid any after-sales issues.

fiberglass cloth for surfboards products are kept in a safe inventory so that we can deliver products to customers whenever they require it. The annual volume of our products could reach 5 million meters. The average time to deliver our products typically is around 10-15 days, the delivery speed is fast, for over 3000 customers around the globe. We export to over 20 countries around the world.