Introduction of E-Glass Woven RovingE-glass woven roving is a kind of material that must be familiar to many people, because it not only has important applications in buildings but also occupies an extremely wide range. It is powerful and hence you can get a lot of beneficial advantages for your projects. This article aims to cover the ins and outs of E-Glass Woven Roving, how it functioned, where it utilized as well as what should you consider when selecting one.

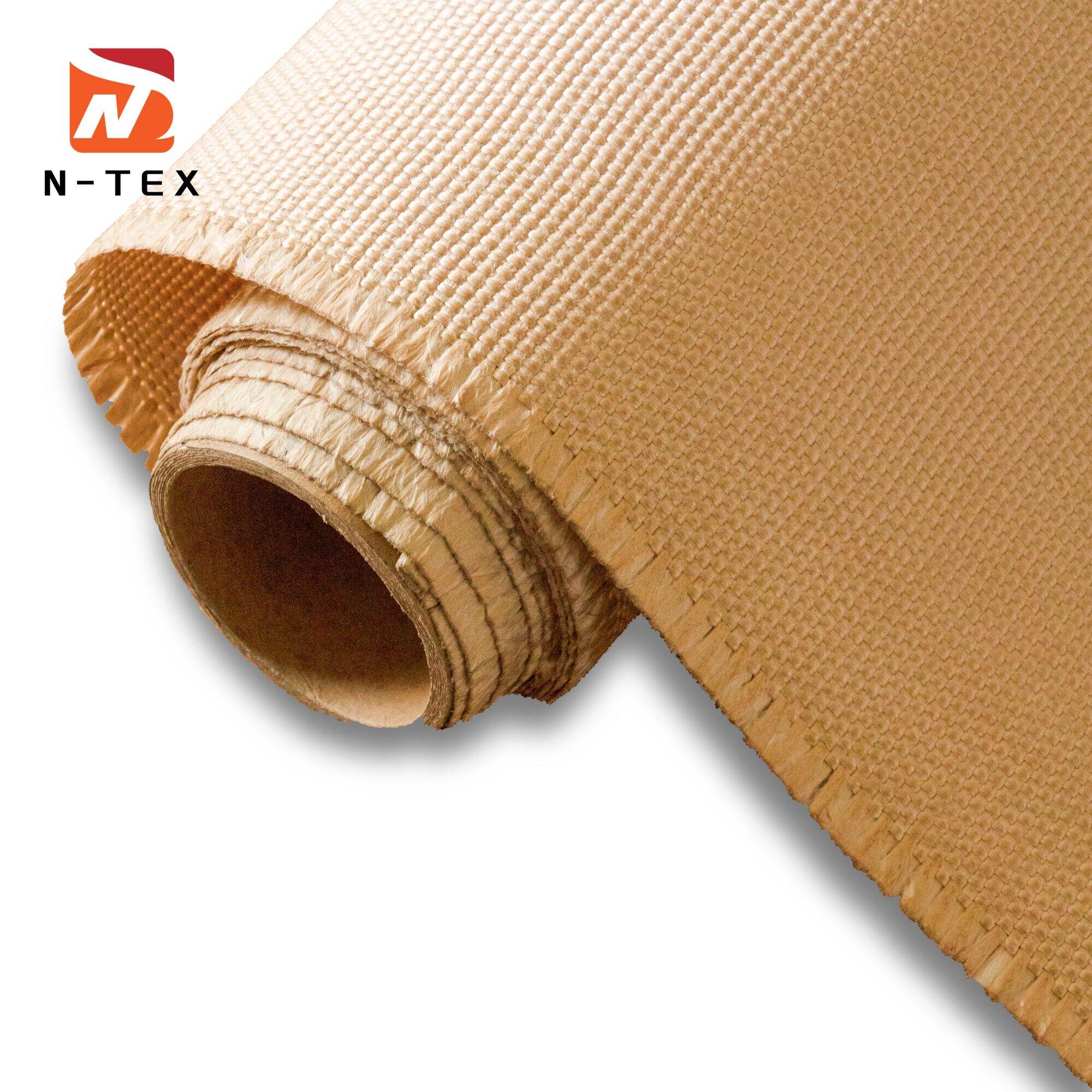

Fibers or also called tiny pieces of glass are the major component that makes up E-Glass Woven Roving. The flat sheet is woven from a new type of these fibers and intertwined. These fibers are also coated with a glue resin that makes the thread even tougher. This glue helps to adhere the fibers and make them stronger. This material is known to be durable, it can withstand high heat conformation and various chemical strikes.

Highlights; Increases strength and extends life of productsE Glass Woven Roving is used in a variety applications that utilize the Hand Lay-up or Robot process. This material can be used to reinforce and make heavy the items that are either lightweight or easy damaged. The E-Glass Woven Roving is a seamless mat using both fiberglass and resin or other reinforcing materials. It is a mix that can withstand most force and has many uses.

We can take the E-Glass Woven Roving as an example, it is used for making boats and sport roadsters. It makes the bodies of these vehicles stronger and longer lasting. Furthermore, it is experienced in construction of buildings by providing support to their walls, roofs and floors which makes them stronger to resist different forces applied over them causing long term life.

This is especially true of E-Glass Woven Roving, which plays a critical role in the marine industry where it goes into making boat and yacht hulls that require to be very tough because they receive their fair share of battering from water. They have also created jet skis, surfboards and even other water boards which offer superior protection as well as durability.

There are many different aspects that need to be evaluated when you are choosing E-Glass Woven Roving for your project. The very first thing you want to think about is what material thickness do I need for my particular application. Copyright Cable News Network, Inc. and Scripps Media, Inc. All rights reserved Higher gauges are considered to be thicker, stronger sheets that may lead a variety of duties however the additionally provide you with farther more economical yet pricy.

Once again, you would have to also think about the form of resin or fiberglass it will be combined with this most likely so happen as well subsequently kind involving E-Glass Stitched Roving. Some resins are work better with different kinds of fiberglass material, thus it is important to do your homework and make sure you choose the right combination for your application.

Our company manufactures mainly silica mats and super mats. To satisfy the demands of our customers we are able to customize our products by using different colors and coatings. We also provide e glass woven roving. We also have various sizes of fire-blankets which can be used for high-temperature operations as well as fire safety and other fields.

Our company is very rigorous on the quality control of our products because we always hold that the quality of products is the foundation of a company. Before we ship, each product is examined for the highest quality. We also check the thickness, weight in grams and the color of the product to avoid any e glass woven roving problems.

Our products are kept in a secure inventory, so that we are able to e glass woven roving the product to the customer in the moment they require it. Our annual products can reach 5 million meters, the normal delivery time typically takes between 10 and 15 days. Delivery speed is fast, for more than 3000 customers around the world, and exports to over 20 countries in the world.

Nanjing Xinwei High Temperature Material Co Ltd is a professional producer of high silica fabrics that covers 220 000 square meters There are four production lines at the factory The capacity of our production can exceed around 200 000 meters per e glass woven roving and our inventory is adequate to ensure the first delivery We have customers across the globe and are determined to provide the best standard of service